Examensarbete. Correlation and optimization of theoretical 3D laser cutting simulation

Master Thesis at Gestamp HardTech. Department: TechCenter

Correlation and optimization of theoretical 3D laser cutting simulation

Gestamp HardTech in Luleå is part of the global Gestamp group which develops and manufactures components for the automotive industry. Gestamp HardTech serves many well-known customers and specializes in the production of press-hardened components.

With the global aim of reducing CO₂ emissions and increasing safety in next-generation vehicles, innovative design and lightweight solutions are essential. The press hardening process plays a key role in this transformation. Gestamp HardTech was the first production plant in the world to work with press hardening and has extensive experience and expertise, supported by an in-house R&D center that supports Gestamp globally.

Background

TechCenter is one of the R&D groups in Luleå, working with definition and optimization of production planning for press hardened parts within the global Gestamp organization. The documentation provided from TechCenter to internal sales departments forms the basis for all global press hardening quotations provided from Gestamp. Needless to say, accurate calculations and simulations are of outmost importance to provide accurate quotations to Gestamp’s customers.

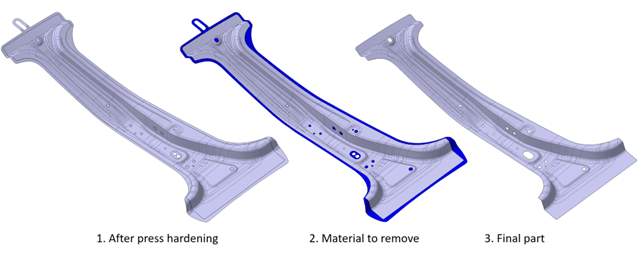

A press hardened component is manufactured from a flat sheet of steel, shaped with massive presses into the desired shape. Commonly, the flat sheet will have some additional material added depending on i.e. customer tolerances and shape complexity of the final part. One of the main cost impacts for a press hardened component is to then in a secondary operation remove this excess material, using 3D laser cutting machines.

Achieving the time required for this operation is currently formula based. However TechCenter is working on implementing a simulation based method of evaluating a 3D-geometry to further improve the accuracy of the laser cycle time evaluation. However, initial correlation tests indicate a substantial discrepancy between simulated values and actual values from production.

Goal

Perform additional correlation studies based on real life production results. This benchmarking should be carried out both through comparison with existing simulation tools from Gestamp’s laser machine supplier as well as physical testing in real-world conditions. After testing, an optimization of TechCenter’s in-house developed laser cutting evaluation should be performed.

Who are you?

You are a student enrolled in an engineering program with a technical focus, such as mechanical engineering, industrial design, or a similar field. You should have a strong interest in problem-solving and a passion for technology.

What we offer

· An opportunity to work with state-of-the-art technology, shaping the future of the automotive industry

· A unique position bridging theoretical R&D and practical production environments

· Paid compensation

Time and duration

30 hp with start in beginning of 2026

Contact

Per-emil Back

Manager R&D Center Luleå

Gestamp HardTech

+46920 47 42 46

- Avdelning

- R&D

- Platser

- Luleå

Om Gestamp HardTech AB

Gestamp är ett tekniskt mångsidigt företag som är verksamt i över 20 länder och med ett team på mer än 40 000 personer av 90 nationaliteter. Vi är den mest erkända billeverantören i världen och producerar för mer än 900 modeller från de största fordonstillverkarna.

Vi på Gestamp HardTech utvecklar och tillverkar lätta och hållfasta säkerhetsdetaljer till fordonsindustrin. Produkter som ger säkrare och mer miljövänliga fordon.