Examensarbete - Crash Cart Calculation Model

Crash Cart Calculation Model

- Master Thesis at Gestamp HardTech in Luleå

Department: Research and Development, Crash management systems

Background

Gestamp R&D in Luleå is part of the global Gestamp group which develops press hardened components for the automotive industry. Gestamp’s R&D office in Luleå currently employs around 65 engineers.

Product development work is performed in close collaboration with our clients where physical testing, finite element analysis and external customer visits is a part of the daily working routines.

Validation of crash performance is done in our testing facility in Luleå where tests utilizing a crash cart, drop or pendulum tower in speeds up to 50 km/h are used as well as hydraulic equipment for static testing.

Crash testing of Crash Management Systems (CMS)

One of the stages in developing a Crash Management System (CMS) is component testing. This is done to validate the design and to confirm that it correlates with the simulation models. To get as accurate results as possible it is necessary to have good CAE model that represent the testing environment.

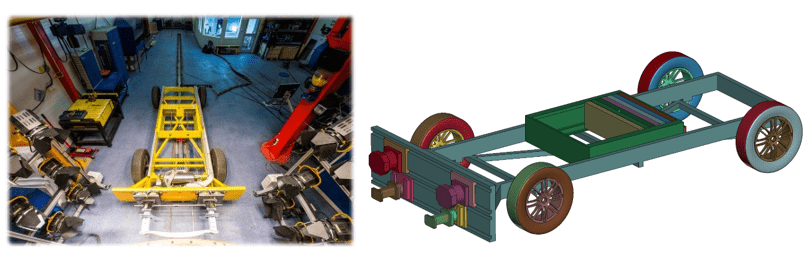

The simulation model of the crash cart we use today is derived from previous master thesis. The model is improved during the years but is continuously development in order to improve correlation. The present simulation model consists of a rigid structure that do not consider the elastic behavior of the physical test cart. We see that the elastic behavior of the crash cart is of great importance in order to achieve good correlation between test and simulation.

Figure 1: Crash cart used in validation and simulation of Crash Management Systems.

Purpose

The main purpose of this thesis is to build and evaluate a finite element model of our crash cart that is used in component testing of Crash Management Systems. The model will then be compared against physical tests in order to validate the result of this master thesis. The result will be used in the day to day development and will lead to lighter and safer components in the cars of tomorrow. The complete crash cart needs to be modeled in CAD before creating the simulation model. This initial step is of great importance and sets the level of accuracy for the final simulation model.

Goals

- Create a finite element model of the crash cart that improves the correlation against test.

- Propose possible design changes of the physical crash cart in order reduce the elastic behavior in test.

Execution

- Literature study – Evaluate what kind crash carts other test institutes uses in crash testing.

- Implementation – Implement the Crash Cart Calculation Model into Gestamp’s current methodology and simulation environment.

- Evaluation – Evaluate the simulation model by crash simulations and compare the result with crash testing.

- Documentation – Document your work continuously in a report.

Who are you?

You are probably studying Mechanical Engineering or an equivalent program. Knowledge of CAD and FEM are required.

Estimated Duration

30 hp with start in 2025 (ECTS – corresponding roughly 5 months full time).

The scope of this thesis is adopted to one student.

Contact

Kenneth Isaksson

Teamleader, R&D

kisaksson@se.gestamp.com

073 661 46 81

We’re looking forward for your application. If you have any questions regarding a Master’s thesis or Gestamp feel free to contact us.

- Avdelning

- R&D

- Platser

- Luleå

Om Gestamp HardTech AB

Gestamp är ett tekniskt mångsidigt företag som är verksamt i över 20 länder och med ett team på mer än 40 000 personer av 90 nationaliteter. Vi är den mest erkända billeverantören i världen och producerar för mer än 900 modeller från de största fordonstillverkarna.

Vi på Gestamp HardTech utvecklar och tillverkar lätta och hållfasta säkerhetsdetaljer till fordonsindustrin. Produkter som ger säkrare och mer miljövänliga fordon.

Examensarbete - Crash Cart Calculation Model

Läser in ansökningsformuläret